How to Rip Narrow Boards with a Circular Saw?

As power tools are not a matter of joke, they can be pretty dangerous sometimes. So, without knowing the appropriate use of a circular saw may lead to many unwanted occurrences. Before jumping on the process, you need to acknowledge every detail to rip narrow boards with a circular saw.

But don’t worry, if you are looking for a reliable guideline of how to rip narrow boards with a circular saw, then you are in the right place.

How Does Circular Saw Work Instead of a Table Saw?

Most of the carpenter use circular saw as a regular portable cutting tool. It comes with a powerful motor and fast-spinning blade to provide a straight cutting experience. It can easily work as a substitute for a table saw.

Average carpenters usually get confused with this tool while it comes to the board cutting. The only reason behind it is that they are not guided properly. As they are not aware of the G clamp working process, they find it more difficult.

In contrast, many professional woodworkers like to use it for precise cutting. Therefore, they believe that it is a simple tool to use in their workshop. However, its multipurpose working ability makes it a perfect tool for any DIYer. If the right blade is attached in the right place, then it will give outstanding performance and get your job done very quickly.

What Types of Tools do You Need?

You should have some usual working tools. Those are,

- A regular pencil for marking the rip line

- A tape for measurement

- A board, which must be longer and broader than the cutting board.

- Two clams for attaching purpose.

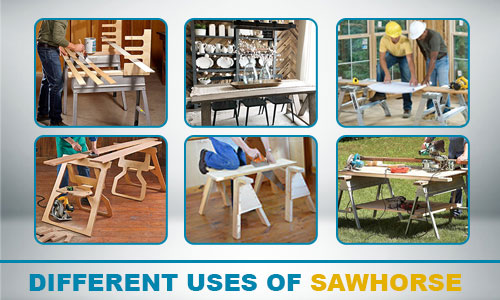

- A stand to place the board you need to cut

- A square for line drawing

- Safety glasses.

- Gloves for extra security

How to Rip Narrow Boards with a Circular Saw? The Perfect Way

For cutting anything, we usually prefer a table saw. What if you have the circular saw instead of the table saw? No worries, we have summed up all the major and minor instructions that will take you through it step by step.

Step-1 Choosing the Right Surface

Firstly, you have to take a broad and straight wood for giving support as a platform. In this case, more extended slabs will accelerate the cutting process by providing additional support. However, the slab should be thicker than the board you are going to rip.

Step-2 Clamping the Circular Saw

The clams should be held the circular saw sole firmly. You have to clam the sole at two different points. Recheck if the sole is adequately set or not because loose-fitting will enough to ruin your whole job. You can go for the following recommended clamps, which are convenient enough.

- Bessey GSCC2.524 Bar Clamp

- Tekton Mini 6- inch Ratchet Bar Clamp

- Bessey LM2.004 LM Bar Clamp

Step -3 Ripping Line Marking

In this term, measurement tape will lead you to start. Markdown the ripping line by taking measures from the broad side of the narrow board. For example, if you are using a 1:2 thin board, then you have to start from the one-inch side. At the time of ripping, it needs to be half-inch from the end of the board’s wider side. It will be the middle point of the board. Don’t forget to keep a similar distance for all points.

Step-4 Drawing the Line

This step is elementary yet important. If you have done it wrong, it will ruin the entire ripping. You need to joint all the points very carefully with a pencil by using the square.

Step-5 Placing the Clamped Board on The Stand

Now it is the time to place the clamped board on a stamp. If you cannot manage any stamp, you can go for a large table. Make sure that the stand or table is stable enough to hold the boards. Then simply attach them tightly and securely. Don’t let them fit loosely to ruin the project.

Step -6 Adjusting the Blade

The circular need to be paralleled appropriately. If it is not adjusted correctly, it will wrap during cutting. As you are going to cut the board on the table, you need to make the height adjustment of the blade as well. For proper adjustment, you may slide the paper under the blade. Let the paper pauses under the blade smoothly.

Step-7 The Process of Ripping

It is the final step, where you need to hold the saw with both hands firmly. Try to hold it at the end edge of the narrow board. Now it is the time to begin the cutting. Do it with minimal pressure for a smooth outcome. You have to remember two crucial facts. The first one is, you cannot pressurize the saw forward. The other one is, you have to finish the cut with one try. If you take too many pauses in cutting, it will not give the fine cut.

If you face any problem, then simply turn off the saw. Then clear the blade and restart the machine again. When you almost reach to end of the board, stop the saw. Let the blade rotating be stopped, then take out. Otherwise, it will lead to any accidents.

Some Safety Tips that You should follow

- It is advised that always wear safety glasses, no matter what you are cutting.

- Try to hold firmly with your two hands, so it doesn’t push you back.

- Try to use a sharp blade

- The cords should be in a safe place while cutting

- If it makes noise while cutting, it is better to use a hearing protector

- Don’t forget to unplug when you are done with cutting

- Avoid loose clothes, which will make you uncomfortable to do the job.

- If you are facing problems to operate the saw, then consult with saw experts before using.

Buying Guide for Circular Saw

- The motor mainly determines the powerful performance of a circular saw. So, try to check the efficiency of the motor before buying it.

- The speed is another crucial fact to concern. To make your cuts faster, you have to require high speedy cutting capacity.

- As you are going to cut the hard material like wood, you need to focus on the durability of the saw as well. Flimsy saw may break and ruin your project.

Conclusion

So, we hope that the given guideline will be effective enough to direct you to cut a long and narrow board precisely. So, how to rip narrow boards with a circular saw is no longer a headache. All you need to do is that, to be well prepared with all the safety equipment. And don’t forget to check the quality of the circular saw blade before using it.

Circular saw mainly comes with various cutting features and performances. They are simple and easy to operate. So, it is advised that, try to find the best circular saw by using our buying guide to get a fantastic outcome.

Table of Contents