Which are Proper Bit for Plunge Router

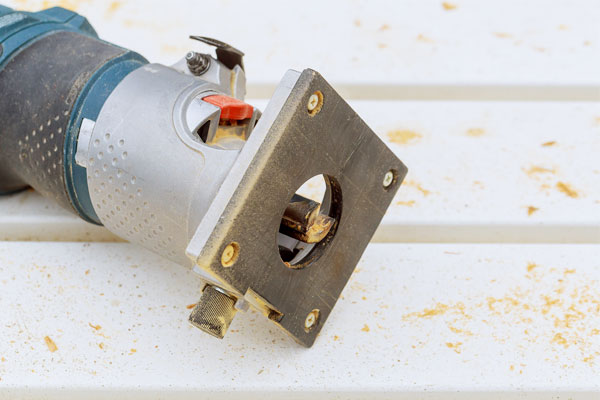

A plunge router is a useful power tool for every workshop and ideally suited for any type of delicate work including cutting inlays, grooves, dados, etc. With growing popularity often a question arise about the bit for plunge router like: is there any specialized bit designed for plunge router? Or which are suitable bits for plunge router. Well, here is a small article with the answer of these questions. Hopefully, you will get all your answers here.

Selecting the Right Bit for Plunge Router

To have a perfect cut you will need a perfect bit for your plunge router. In the market, there are different types of bits available for routers. Among them choosing the right one is a bit tricky.

Actually, I am not aware of any specially designed bit for plunging however for different purposes you can use the different bit. According to my experience, I can say for plunging you need a bit that has a sharpened edge that goes across the end of the workpiece. For normal plunging, you can use a straight bit with a brushed up edge.

If you want a deep cut as well as bottom of the cut to the cleanest, I would suggest using an up-cut spiral bit for your plunge router as it is perfect for plunge cutting and can clear the chips from the blind hole. Spiral up cut bits not only evacuate the chips as they cut but also leave the cleanest surface bottom. For example- HSS or solid carbide end mills that can be used for cutting metal but trust me! They can do an outstanding job on wood too.

Spiral down cut bits are kind of similar to spiral up-cut bits, but the flutes run in the opposite direction. This bit also leaves a clear surface, however needs a slower rate than the spiral up-cut one. Another difference between these two is while spiral up-cut bits can do deep cut on the surface, spiral down cut bit is suitable for a shallow cut.

There are also combine up cut and down cut flutes in one bit. If you think buying one is better hassle-free than buying two, then you can go for them but As far I know they are quite expensive than the normal ones and perfect for CNC operation.

Well if you want to know about my experience then I would say till now I am happy with the edge cut by my straight bit (my router bits has required sharpened edge) so never feel the necessity to buy another type of bits. But depending on your job and purpose you can definitely buy spiral up cut and down cut bits, however before trying the bit on the workpiece, it’s better to try that on scrap first.

Conclusion

I hope you have got the answer to some important questions. Always remember, safety is the first and foremost priority for every work. So while working with routers please follow the safety precautions thoroughly. Always put on safety goggles and overall during working with woods, and also stay aware of your finger. Happy Crafting!!!

![How To Clean Stainless Steel Appliances? [Tips & Tricks]](https://woodworkingarena.com/wp-content/uploads/2018/08/Stainless-Steel-Appliances-1-768x511.jpg)

![How To Sharpen a Table Saw Blade? [Step By Step Guideline]](https://woodworkingarena.com/wp-content/uploads/2021/03/How-To-Sharpen-a-Table-Saw-Blade.jpg)