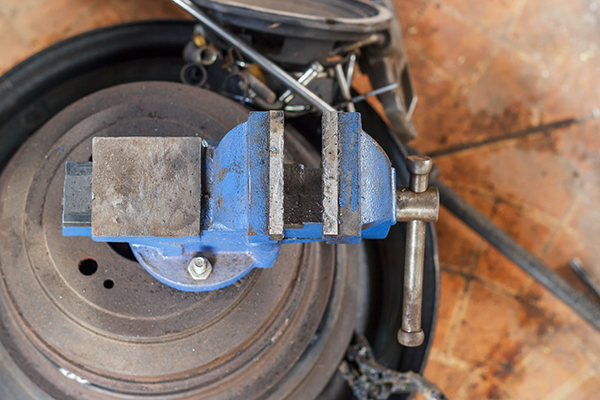

Bench Vise or workbench vise is a common hence essential tool for woodworking, metalworking, and many other manufacturing applications. Thus this tool is an integral part of your workshop. Although bench vise is a simple machine and does not require lots of maintenance, however some routine care can prolong its life span and a good artisan always takes good care of his tools.

Standard Height to Set the Vise

A vise is usually attached directly to a workbench to hold the workpiece during sawing, planning, or drilling. So to avoid any uncomfortable poses the vise should be placed conventionally at a proper height. To be more exact the vise should be mounted at such height where the operator can perform his duty with his elbow on the top of the jaws or else it will be difficult to play his duty. To achieve the right height you can either raise the workbench or place a floorboard on the floor so that the operating person can climb onto it to complete the work.

Since jaws are a vital part of bench vise the workpiece should be fastened to a suitable height. From my point of view, it should be at least 1 cm from the jaws.

Types of the Bench Vise:

- Woodworking vise

- Heavy-duty vise

- Medium duty bench vise

- Pipe vise

- Chain vise

- Yoke Vise

- Metalworking vise

- Vacuum vise

- Cross Slide Vise

How to Choose

My experience of using Vise for a quite long time says before buying a vise there are few factors you should consider.

Purpose

The first thing the purpose of the vise. Woodworks, mechanists, and welding need a specific type of bench vise, but that is not the best choice for own home-based workshop. For general household DIY crafts and works, 4 to 5-inch vise is good enough to handle the maximum task (the measurement is the length of jaws from one end to another end and these will have maximum contact with the workpiece.)

Depth of the Throat

The depth of the throat is another matter to consider. It is measured from the top of the jaw to the top slide below it. The longer the depth is, the longer workpiece can the vise hold more securely.

Weight and Buildup of the Piece

Before taking the final decision compare between the two best options you selected. You might find one feature similar but there might be a difference in another. Like maybe the Jaw length and depth are the same but the weight is different. Now if you want to use it as an anvil, you have to confirm whether it can take the abuse. How wide the vise open is another limiting factor so do not forget to unwind the device fully to make sure it can handle the work you want to buy it for. Another important matter you have to keep in mind before buying the vise is your workbench is strong enough to accommodate it.

Vise Maintenance

Keep your Vise Dry and Clean

Nobody knows better than us that vise gets wet during use either from the wet workpiece or from fluid or maybe from your water bottle that spills accidentally during work. Moreover, vise is exposed to moisture as many of us keep it in the garage, workshop, or damp basement. The finish of the equipment might hold the corrosion for a while but trust me! Eventually, the moisture will take over and your vise will be caught up by rust. So it is really important to keep your vise dry.

During work, the shavings of the workpiece can accumulate on different parts of the vise especially on the movable parts, nuts, and shafts. I always keep a rag to wipe off all the dirt from the threaded and moving parts and then cover it up with an old T-shirt and then put a garbage bag to keep it clean, dry, and protect from dust

Keep the Vise Lubricated

As the vise is pretty simple equipment we tend to maintain them relatively infrequently, however, it is harmful to your vise. To keep your vise in tip-top oil and lubricate the joints on a regular basis. Usually, each vise manufacture has a set of recommended lubricants that match the equipment, however, my favorite one is dry graphite lubricant and it is one of the most recommended lubricants. Dry lubricants keep the tool free from dust accumulation however you can also use wet lubricant but in that case, you have to diligent to prevent dust buildup.

To apply lubricant or oil on the sliding section, open the jaws completely and put some oil/grease/lubricant. Then move the sliding in and out for few times and distribute the lubricant evenly. Avoid putting wet lubricant on the rotating base/joint as this can reduce the clamping force.

Clean Rust

If rust appears on your tool it is better to use rust cleaning chemicals. Simply apply the chemical to the rust and leave it overnight. After that scrub the rusted area and wash it with water. Then dry your vise and rub the water from joints with the cloth carefully

Repaint

after wiping off all the water repaint the tool with a fresh coat of color. It is better to repaint it with rust-resistant protective color.

Replacing Parts

you have to replace jaws few times during the lifetime of a vise. Spare parts are available and guidelines are available online. Just follow that. Trust me it is not that complex.

Conclusion

well! That is pretty much all tips to maintain bench vise. Vises have a lot of flexibility in terms, of use. If you avoid using it for which it is not designed to and follow the tips even the cheapest vise will last for a long time.

Table of Contents